Some of the guys from my club have hardtail bikes and I have ridden those a couple of times.

Slowly the appeal of a stripped-down, light, nimble bike with a strong vintage flair revealed itself to me and there was no going back.

I toyed with the idea of a 1200 twin-spark Sportster chop for a while (we had an engine in the workshop that eventually went into a tarmac-ripping beast another friend built) but that just didn't happen.

Then another friend from the club decided to sell his BSA café racer and everything that came with it and I was lucky enough to snatch that at the time.

I kept it for a few years, used it as a bar hopper, went on rallies, on long trips, had fun with it and then sold it on to another friend. What's that got to do with this you say?

Well, amongst the things I got when I bought that bike (a small box of spares, the aluminium tank, the shorter seat, etc.) was an A50 engine, which I kept.

It seemed almost natural to plan a hardtail bike with that engine, although at first I had imagined a Rickman-Métisse bike,

That wasn't really going to happen though, for various reasons, so the A50 got put on the back burner.

Then the whole chopper thing resurfaced and with it came thoughts of wild summer rides, sleeping under the stars, going on a big trip with a small bike and with all your gear in a roll-up strapped to a sissybar.

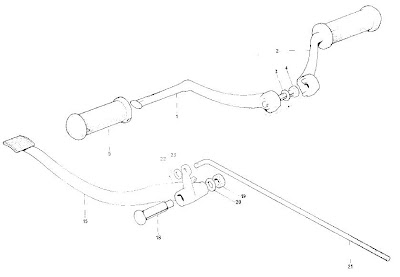

I had the engine. I had the handlebar, the mufflers and a carburetter. This thing was practically building itself!

That was it, time to decide on one thing: it would be a rigid/hardtail framed BSA.

Then came the dozens of variations on every component and trying to decide the overall look I liked best. Since there is more than one type that I really like, that was always going to be difficult and it is possible that this bike's shape will evolve.

I realised that what I liked best in terms of proportions and stance was an original front loop from, say, a Triumph Daytona or a Bonneville, with a straight-to-axle style hardtail bolted on.

The reason for this preference is probably down to a single photograph in a book called "hot rods and pin-ups" by David Perry of an orange 1970 TR6 hardtail.

I thought I could get a Triumph front frame (and I had even sourced one locally, though it was pretty badly mangled) but there were never any guarantees it would fit.

Not being the most skilled guy out there I wasn't sure what would have gone into modifying a frame and making it so that everything could line up correctly (sprockets and chain for one).

After the local Triumph front loop turned out to be too dodgy I started looking at British-only as a possible source of frame + bolt-on hardtail. Having bought spares from them in the past I'm pretty sure they would have been able to deliver.

But then something else happened that I hadn't thought possible in the first place. There was a frame that was exactly what I was looking for. At just the right time. Uncanny.

Enter Lowbrow Customs. No introductions necessary (unless you've been living in another dimension where there are no cool rides, in which case please go check them out right now: www.lowbrowcustoms.com).

And sure enough in their stock they had a variety of complete frames as well as bolt-on/weld-on hardtails for Triumph and BSA. They've since expanded their range and if what you're after is a tidy little chop with a proper frame, they have what you need.

The best part was, there was a complete frame (all welded, no bolt-on parts) for the A50 engine (or "motor" as they say over there). Score! and you could have it in lots of flavours too: from standard wheelbase up to six inches longer at the back.

From standard height to 2.5in lower. With or without a battery base, with a looped or straight-to-axle rear end. That means something like four dozen frames to choose from just for your particular engine!

So you can imagine that just choosing the specs for the frame took some thinking. In the end the winner was:

4in stretch, with battery base, 1in drop and with straight rails. Phew.

Over to David Bird who actually makes the frames and is clearly very talented at what he does.

Both him and the guys at Lowbrow were incredibly quick in getting everything (it wasn't just the frame I got from them...) packed and shipped over to Rome.

I like the fact that this frame has already travelled more than 5,000 miles... I got some catching up to do!